IN'O sensor

Declaration of conformity

Download the declaration of conformity

Presentation

The IN'O sensor is a LoRaWAN class A sensor that manages two different power supplies: one is external and may range from 9V to 24V, the other one is internal on the battery.

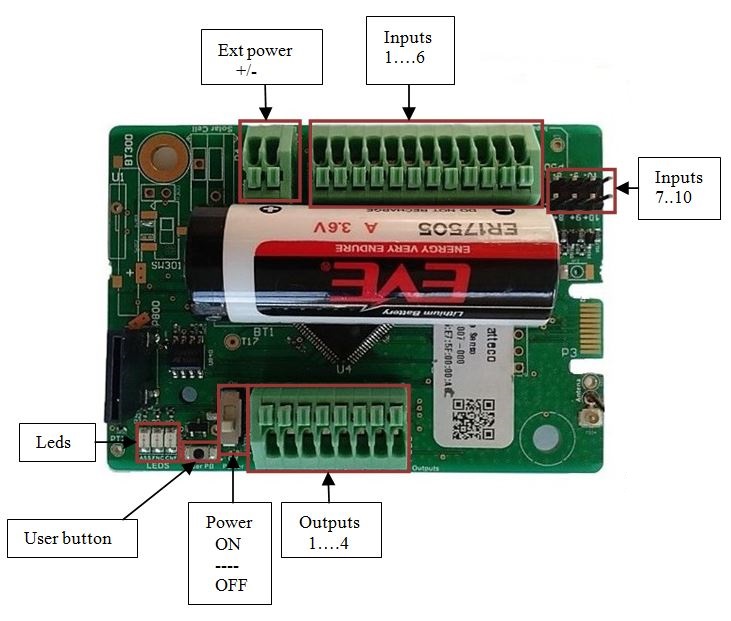

The IN'O sensor incorporates 10 digital inputs, and 4 optocoupled outputs. It also includes an external antenna.

The level or a counter can be transferred to the different inputs. It is also possible to get the voltage of the power supply, and to switch ON, OFF or toggle the outputs.

Family code

The family code of IN'O sensors is:

50-70-016-xxx Class A

50-70-087-xxx Class C

Electronic input/output

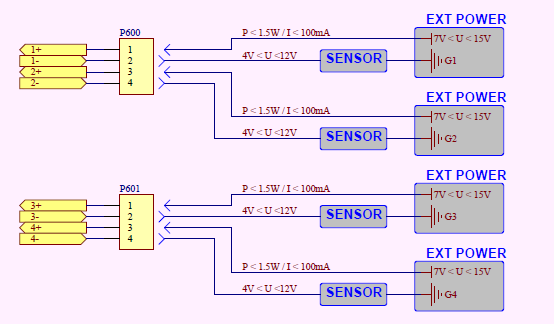

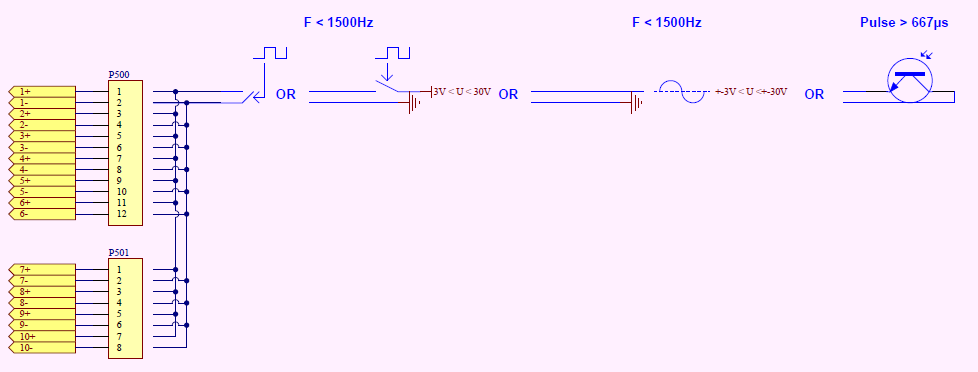

The schematic of the different inputs and outputs of the IN'O sensor is illustrated below:

Electrical schematic example for inputs

→ Due to software limitation, the maximum frequency is 100 Hz on each input

Electrical schematic example for outputs

On the output, there is a 3V voltage drop. The maximum current is 100mA (or maximum power of 1.5W):

Installation and operation

Installation

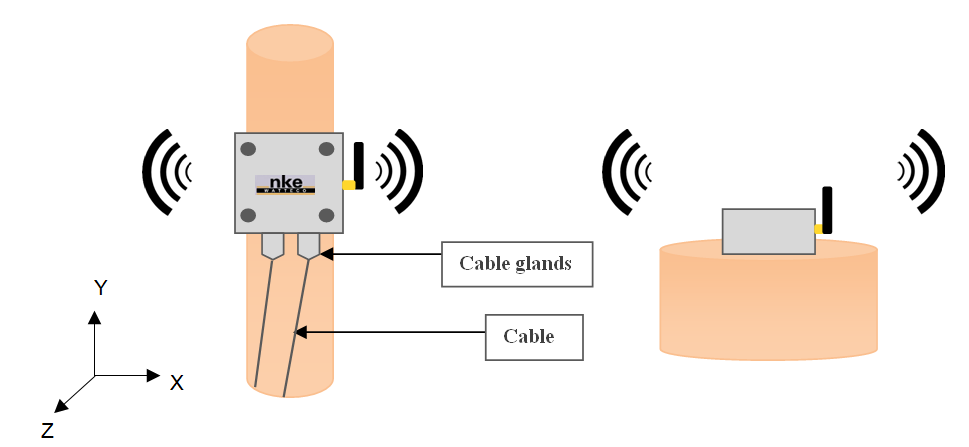

The housing is intended to be installed inside or outside a building but it must be protected from vertical water spray and direct sunlight.

The product is delivered disassembled. This enables the connection to the screw terminals.

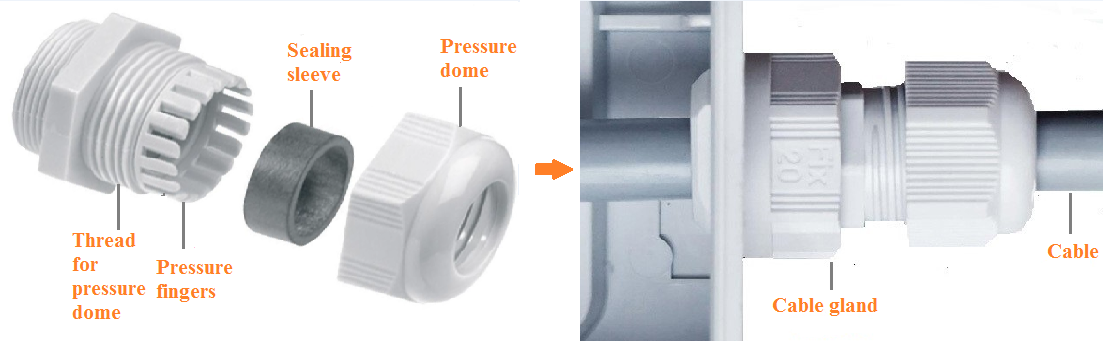

Before connecting your cable strands to the product’s screw terminals, you must insert the cable gland's nut and the seal.

Then connect the wires to the Inputs and Outputs that will be used:

For the connectors, we recommend using several 20-26 AWG single wires. As the connectors pinch the wires plugged inside approximately 4mm from the wire end, strip the wires over a length of approximately 5 to 6mm before plugging them into the connectors.

For Inputs from 7 to 10, the connectors shown in the following pages can be used:

http://fr.farnell.com/molex/16-02-0088/contact-femelle-24-22awg-a-sertir/dp/2751584

http://fr.farnell.com/amphenol-fci/65039-035lf/mini-connecteur-2p/dp/1211646

http://www.ldlc.com/fiche/PB00193109.html

http://fr.farnell.com/amphenol-fci/65801-002lf/connecteur-2-voies/dp/1103901?CMP=GRHB-OCTOPART

Once the assembly is complete, the casing can be closed.

The housing is compatible with the following DIN rail adapter:

For more information about the casing, please visit: www.spelsberg.com

Radio propagation

In order for the sensor to operate correctly, the number of obstacles should be limited in order to avoid excessive radio wave attenuation. It is also important to place the sensor as high as possible. Also, the antenna needs to be directed upwards.

Autonomy

The information in the table below represents how long the battery can last. It is based on the default configuration at ambient temperature (+25°C) within the optimal operating range of the sensor via a LoRaWAN network (one uplink frame), when the spreading factor used is SF12.

The disposable battery has a 3.6Ah capacity, of which 85% is used.

| Transmission periodicity | Battery life | Battery life (with 3 Input contacts closed) | Battery life (with 6 Input contacts closed) | Battery life (with 1 Output closed) |

|---|---|---|---|---|

| 1 frame/2 hours | +15 years | 12 years | 9 years | +1.5 years |

| 1 frame/24 hours | +15 years | +15 years | +15 years | +2 years |

A value of 3µA of consumption is added per input connected (contact closed).

When one of the outputs is ON, a consumption of 160µA is added. Due to this consumption, it is highly recommended to use an external power supply.

Human Machine Interface

Once the device is installed, switch the power ON.

There are three LEDs on the IN’O devices:

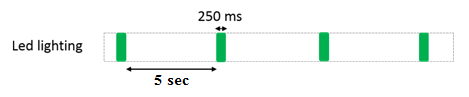

ASSN: blinking until the association with a network is done.

FNC: blinking every minute while an input is activated.

CNF: blinking in configuration mode.

- A user button is available to enter the configuration mode. "Void" frames are then sent every minute for 10 minutes.

Standard reports are disabled in this mode.

| Way to trigger it | One press on the USER button or specific ZCL command |

| Way to stop it | Another press on the USER button or specific ZCL command |

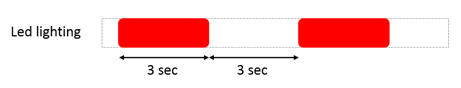

| Effects on the sensor | The CONF led (red) blinks (3 sec. OFF, 3 sec. ON) and the sensor sends an uplink frame every minute. The blinking is illustrated below this table. |

| Duration | The configuration mode lasts 10 minutes when it is triggered by pressing the USER button |

- A reassociation procedure can be requested if no downlink frame is received by the sensor during a given periodicity (4 days by default) or if a given number (100 by default) is reached or in case of failure (no acknowledgement received) by sending an applicative frame to the sensor or via the sensor's IHM.

The sensor keeps the AppEUi and DevAddr configured, Confirmed/Unconfirmed configuration and all applicative configurations. However, LoRaWAN configurations (channel, data rate…) are lost.

| Way to trigger it | Three short presses on the USER button or ZCL command from LoRaWAN cluster. |

| Effects on the sensor | The ASSO LED (green) blinks as the “no commissioned sensor” LED is lit. |

- A factory reset is available on Watteco’s sensors. It deletes all the applicative settings saved in the flash memory (i.e.: configured batches and reports will be deleted).

The sensor keeps the AppEUi and DevAddr configured. However, LoRaWAN configurations (channel, data rate…) and applicative configurations are lost.

| Way to trigger it | Two short presses and one long press for approximately 7 seconds on the USER button. |

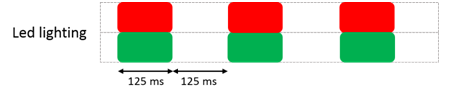

| Effects on the sensor | The CONF LED (red) and ASSO LED (green) blink at the same time briefly. All the applicative settings (for batches and reports) are deleted. The blinking is illustrated below this table. |

Applicative layer

Codecs are available to decode frames: Downloads

The IN’O device implements “ON/OFF” and “Binary Input” clusters, associated to their Outputs and Inputs. The corresponding clusters between the connectors and the EndPoint are shown below:

| Connector | End Point | Cluster | Fctrl |

|---|---|---|---|

| Input 1+/1- | 0 | Binary Input | 0x11 |

| Input 2+/2- | 1 | Binary Input | 0x31 |

| Input 3+/3- | 2 | Binary Input | 0x51 |

| Input 4+/4- | 3 | Binary Input | 0x71 |

| Input 5+/5- | 4 | Binary Input | 0x91 |

| Input 6+/6- | 5 | Binary Input | 0xB1 |

| Input 7+/7- | 6 | Binary Input | 0xD1 |

| Input 8+/8- | 7 | Binary Input | 0xF1 |

| Input 9+/9- | 8 | Binary Input | 0x13 |

| Input 10+/10- | 9 | Binary Input | 0x33 |

| Output 1+/1- | 0 | ON/OFF | 0x11 |

| Output 2+/2- | 1 | ON/OFF | 0x31 |

| Output 3+/3- | 2 | ON/OFF | 0x51 |

| Output 4+/4- | 3 | ON/OFF | 0x71 |

IN’O incorporates the following clusters:

| cluster | cluster name | managed attributes |

|---|---|---|

| 0x0000 | Basic | All |

| 0x0050 | Configuration | All |

| 0x0006 | ON/OFF | All |

| 0x000F | Binary Input | All |

| 0x8004 | LoRaWAN | All |

| 0x8005 | Multi Binary Inputs | All |

Default configuration

A default configuration is set:

- The device reports each day the counter value associated to input 1+/1- (EndPoint 0 / Cluster Binary Input / Attribute Count).

- The device reports the state of input 2+/2- at each variation with a hysteresis of 2 hours (Endpoint 1 / Cluster Binary Input /Attribute Present Value).

Every change made to the default configuration must comply with the legal duty cycle (for example, the most restrictive in the EU is 0.1%, which corresponds to approximately 1 frame per hour with SF12)

Frame examples

All frames have to be sent on port 125

Standard report

Report

Report of the present value of connector input 1+/1-

→ Applicative payload is: 11 0a 00 0f 00 55 10 01

11: Fctrl (Endpoint=0)

01: current binary value

Report of the current value of the counter of connector input 2+/2-

→Applicative payload is: 31 0a 00 0f 04 02 23 00 00 00 01

31: Fctrl (Endpoint=1)

00 00 00 01: current value of the counter

Configuration

Toggle the output 2+/2-

→The output 2+/2- is the End Point 1; Cluster “ON/OFF” is 0x0006. A specific command 0x50 must be used with payload 0x02 for the toggle.

Applicative payload is: 31 50 00 06 02

31: Fctrl (Endpoint=1)

02: invert the relay state of the sensor

Configure a standard report on connector input 6+/6- Report the value of connector Input 6+/6- every pulse. The value has to be reported at least every 10 minutes, and a minimum time delay of 10 seconds between 2 reports has to be set to optimise consumption: →The value on Input 6+/6- is the End Point 5, Cluster “Binary Input” is 0x000F, and Attribute “present value” is 0x0055. The maximum field has to be 0x800A to have a report every 10 minutes and the minimum field has to be 0x000A to have a minimum time delay between two reports. The delta has to be configured to 0x01 for a report every pulse. Applicative payload is: b1 06 00 0f 00 00 55 10 00 0a 80 0a 01 b1: Fctrl (Endpoint=5) 00 0a: minimum reporting interval (10 seconds) 80 0a: maximum reporting interval (10 minutes) 01: reportable change (1 pulse) →Response: b1 07 00 0f 00 00 00 55 To disable the previous configuration, change the value of the minimum and maximum sending interval and the delta to 0: b1 06 00 0f 00 00 55 10 00 00 00 00 00

Configure a standard report on connector input 1+/1- Report the counter every 5 pulses on connector Input 1+/1-. The counter has to be reported at least every hour: →A counter on Input 1+/1 is the End Point 0, Cluster “Binary Input” is 0x000F, and Attribute “Count” is 0x0402. The maximum field has to be 0x0e10 to have a report every hour and the minimum field has to be 0x0000 to have a report immediately after the right incrementation. The delta has to be configured to 0x05 for a report every 5 pulses. Applicative payload is: 11 06 00 0f 00 04 02 23 00 00 0e 10 00 00 00 05 11: Fctrl (Endpoint=0) 00 00: minimum reporting interval (0 seconds) 0e 10: maximum reporting interval (1 hour) 00 00 00 05: reportable change (5 pulses) →Response:11 07 00 0f 00 00 04 02 To disable the previous configuration, change the value of the minimum and maximum sending interval and the delta to 0: 11 06 00 0f 00 04 02 23 00 00 00 00 00 00 00 00

Configure the polarity on connector Input 1+/1- →Write attribute no response: 11 05 00 0f 00 54 10 nn 11: Fctrl (Endpoint=0) nn: current polarity of the sensor (normal : 00, reversed: 01)

Configure the edge selection on connector Input 1+/1- →Write attribute no response: 11 05 00 0f 04 00 18 nn 11: Fctrl (Endpoint=0) nn: the current edge selection ( 01: falling edge, 02: rising edge, 03: rising and falling edge, 04: polling)

Configure the debounce period on connector 3+/3- →Write attribute no response: 51 05 00 0f 04 01 21 00 7D 51: Fctrl (Endpoint=2) 00 7D: debounce period (125 ms)

Batch report

Configuration

• Configure a batch report on connector input 6+/6- and connector input 5+/5-:

Timestamp and record the input 6+/6- every 100 pulses, and timestamp and record the level of input 5+/5-. A report has to be sent at least every 10 minutes:

→A counter on Input 6+/6- is the End Point 5, Cluster “Binary Input” is 0x000F, and Attribute “Count” is 0x0402.

A level on Input 5+/5- is End Point 4, Cluster “Binary Input” is 0x000F, and Attribute “Present Value” is 0x0055.

There are two different measurements to be recorded in the batch, so the tag size has to be 1. Label 0 can be used for counter and Label 1 for level.

For counter, the delta is 100 and resolution 1. For level, the delta is 1 and resolution 1. The maximum has to be configured for all to 0x800a.

Two frames must be sent to configure this batch.

| Label number | Tag label | Tag size |

|---|---|---|

| 1 or 2 | 0/1 | 1 |

| 3 or 4 | 00/01/11/10 | 2 |

| 5 or 6 or 7 or 8 | 000/001/010/011/100/101/110/111 | 3 |

| ... | ... | ... |

Applicative payload of the count on input 6+/6- b1 06 00 0f 1d 04 02 00 00 00 80 0a 00 00 00 64 00 00 00 01 01 b1: Fctrl (Endpoint=5) 1d: 0b00011101 => 0001110: size of configuration string after attribute ID (14 bytes) 00 00: minimum recording interval (0 seconds) 80 0a: maximum recording interval (10 minutes) 00 00 00 64: required delta value (size: 4 bytes for attribute Count => attribute type = 23, 100 pulses) 00 00 00 01: required resolution 01: tag value (ob00000001 => 00000: tag label, 001: tag size) →Response: b1 07 00 0f 00 01 04 02

Applicative payload of the present value of input 5+/5- 91 06 00 0f 11 00 55 00 00 00 80 0a 01 01 09 91: Fctrl (Endpoint=4) 11: 0b00010001 => 0001000: size of configuration string after attribute ID (8 bytes) 00 00: minimum recording interval (0 seconds) 80 0a: maximum recording interval (10 minutes) 01: required delta value (size: 1 byte for attribute PresentValue => attribute type = 10, 1 pulse) 01: required resolution 09: tag value (ob00001001 => 00001: tag label, 001: tag size) →Response: 91 07 00 0f 00 01 00 55

To decode the batch reception, use br_uncompress. Type for binary input attribute counter is U32 (10), type for binary input attribute PresentValue is Boolean (1). Hence the following command must be used:

echo “ 26100040405e7692050000004006 ” | br_uncompress -a 1 0,1,10 1,1 ,1

Result

DECOMPRESSION SERIES

cnt: 7 # Batch counter (from 0 to 7)

5778 # Timestamp in seconds of sending of the frame

#Format of data is: Timestamp of Measurement | Label | Value

5689 0 0 # Timestamp: 5689 s Label 0 Value: 0

5777 1 1 # Timestamp: 5777 s Label 1 Value: 1